Industrial Vacuum Cleaners

We have worked with industrial vacuum cleaner manufacturers and power tool manufacturers for many years, gaining deep experience and domain-specific knowledge in this field.

Things to Consider When Designing Electronics for Vacuum Cleaners

- Electrostatic effects are significant in vacuum cleaners and dust extractors. To avoid problems later, address electrostatic issues early in the mechanical design stage.

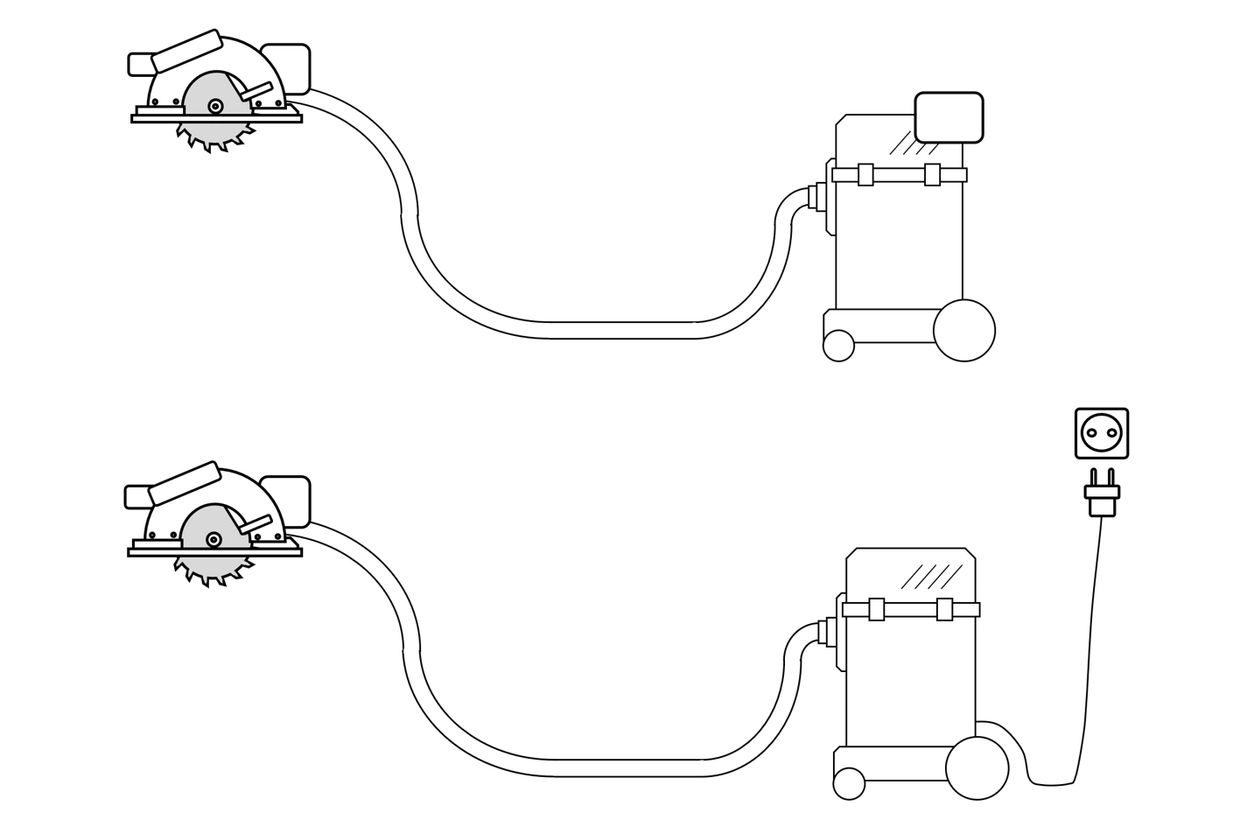

- Long cables behave like antennas. If your design includes long wiring, be prepared to handle electromagnetic compatibility (EMC) issues. Plan time for this in your project schedule.

- Operating temperature matters. Consider the impact of airflow and cooling on the electronics when defining the board’s operating temperature range.

- Universal motors require calibration. If your design uses a universal motor, you will likely need to calibrate the vacuum cleaner’s electronics after the device is partially assembled. Include a calibration mechanism in your design.

- Battery-powered models require careful study. If the vacuum cleaner runs on batteries, review the battery schematic and manufacturer recommendations thoroughly to ensure your connection design is feasible.

- Pressure sensors drift with temperature. Include a mechanism for periodic calibration, as the characteristics of pressure sensors change with temperature.

- …and many other considerations — industrial cleaner electronics design has nuances that are best addressed early in the project.